Course Description

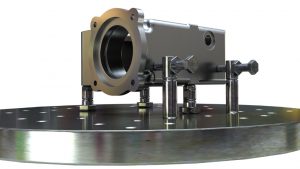

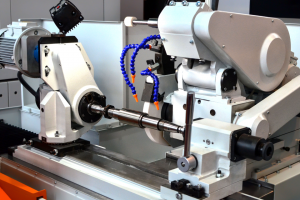

Machining: Cylindrical Grinding Fundamentals introduces learners to the components and operations central to the precision grinding of cylindrical, and even non-cylindrical, workpieces. Using animated demonstrations and other visual aids to break down complex concepts, the course aims to demystify the process of imparting fine surface finish and achieving high tolerances on parts with complex geometry. By the end of the course, learners will understand how a variety of industries—from automotive to ball bearing to aerospace—rely on this downstream metal machining process.

Who will benefit from this Cylindrical Grinding course?

Manufacturing, quality, and engineering functions in an organization that machines product and procures machined components using CNC cylindrical grinders, conventional grinders, or similar equipment.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Machining: Cylindrical Grinding Fundamentals

*upon successful completion

Related Posts

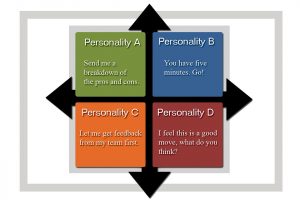

Knowing Customer’s Personality Style Adds Value

Maybe you think the value is obvious. If you can speak the same “language” as the person you are talking with, you can build trust

Online Learning Levels the Playing Field for Students with Disabilities

Online learning has transformed the traditional education model and revolutionized education, offering students with disabilities the flexibility and convenience of learning from anywhere. With the

Cylindrical Grinding in Manufacturing is Fueled by Five Factors

Introduction to Cylindrical Grinding in Manufacturing In modern manufacturing, cylindrical grinding plays a crucial role, emerging as a key process. Let’s explore the intricate world